GENERAL INFORMATION

1. The product must be stocked in a dry place with integral packing. The parquet should be removed only at the moment of installation, if conditions are not correct, it should remain fully wrapped & stored in a dry building.

2. The client has the obligation of verifying the product prior to installation. This entails making certain there is no damage caused by transportation, opening the parquet packages and checking the material. The material cannot be contested once it has been installed.

3. At the moment of installation the average ambient air humidity must fall between 45% - 60% and the temperature should not be below to 18°C.

4. The suitability of the sub-floor must be determined prior to installation, ascertaining that it is clean, compact and of a uniform thickness. In addition, the sub-floor must adhere to the norms designated for the planarity, using a level (straight edge) of 4m ± 2mm. The presence of a vapour barrier must be established. The moisture content should be measured with a carbon hygrometer and should not exceed the values below:

| |

SENZA

riscaldamento a pavimento |

CON

riscaldamento a pavimento |

| Massetto cementizio |

2,0 CM-(Masse) % |

1,7 CM-(Masse) % |

| Massetto di anidride |

0,5 CM-(Masse) % |

0,2 CM-(Masse) % |

The floor fitter should be aware of the colour/tone variations in the hardwood flooring so as to create a homogeneous end result.

In order to permit the natural stabilization of the wood flooring with regards to the ambient conditions, expansion joints must be left on the perimeter of the room. This can be done using wooden wedges, leaving a space of 5-15mm depending on the size of the room (15mm if it large). The wedges must be removed as soon as the installation has been completed. The resulting spaces around the perimeter of the room will subsequently be covered by skirting boards.

The wood floors can be laid Triveneta Parchetti, depending on your needs, using all the main techniques of fixation.

For maximum freedom of composition.

FLOATING INSTALLATION

A floating installation can be assimilated to a unique and/or whole wooden surface which is simply rested upon a sub-floor, and therefore completely free to adjust itself should changes in the environment occur. A floating installation is generally recommended only for engineered flooring, which is comprised of a wooden wear layer and a counterbalance for structural stability. A floating installation is suggested only for 2 and 3 layers flooring with adequate dimensions and thicks.

The installation of these elements takes place directly on the levelled sub-floor surface covered by a thin soundproof mat and vapour barrier. Each of the elements are fixed to one another using a small quantity of vinyl adhesive glue applied in the joints of the elements. Dilation joints should be included in correspondence with door thresholds or rooms with other types of flooring, in order to ensure a smooth transition from one room to the next.

FULL SPREAD GLUED INSTALLATION

An adequate quantity of adhesive should be applied uniformly and in a semi-circular fashion to the installation surface using a notched spatula applicator and working the glue as needed to promote an adequate contact with the element, while following the instructions of the manufacturer and the yield of the product. The quantity of adhesive applied to the installation surface should be proportional to both the dimensions of the elements to be laid and the conditions of the installation surface, in order to guarantee the complete contact of the hardwood flooring elements with the adhesive applied. It is important to take note that an excessive, or conversely, inadequate quantity of glue may be the cause of post-installation defects. It is recommended to not apply adhesive to extended areas of the installation surface to ensure that the glue retains the necessary 'wetness' required for a correct adhesion with the parquet elements.

The installation of the flooring itself begins with the laying of a first row, followed by successive rows until the perimeter walls of the room in question have been reached. At this point, it is important to keep in mind that an expansion joint ranging between 5-10mm should be left between the last elements and the wall so as not to inhibit the subsequent natural expansion of the wood (Note: Do not leave an expansion joint in proximity of the door threshold).

Important Note: In absolutely no case are the joints of the hardwood flooring elements to be glued to one another as this will most likely induce the appearance of fissures during the possible dilation/retraction of the flooring elements due to a variation in the hygrometric conditions of the latter.

The floor fitter should take particular care during the installation so as to avoid the application of the glue on the top layer of pre-finished products, which cannot later be re-sanded as they have already been oiled or varnished. Should any residues of glue on the top layer become evident, it should be carefully wiped away immediately. Once the installation and the cleaning of the flooring has been completed, the application of a water-repelling product (recommended for Oiled flooring) is highly recommended to prevent eventual water or humidity infiltrations that may be provoked during ordinary cleaning and/or maintenance.

NAILED INSTALLATIO

This type of installation is recommended only for traditional solid flooring, thus not engineered. In the case of a nailed installation, the wooden lists must be well adhered to the sub-floor, wooden boards or panels. Prior to beginning the installation, it is wise to first choose the most appropriate wall from which to begin. In order to install the flooring correctly, at least 2 nails (35-40mm) should be embedded at a 45° angle on the tongue joint using a suitable awl. The wooden lists should be placed no further than 30-35cm apart to guarantee stability of the flooring.

UNDERFLOOR HEATING CONSIDERATIONS

What is a heated sub-floor?

A heated sub-floor consists of a cement base of either hydraulic binder or anhydride, with a system of pipes placed throughout it's entire thickness through which a liquid capable of heating a given environment runs through. The under floor heating system is directly connected to the home's universal heating system in order to optimize the heat distribution in relation to the use, placement and exposure of the rooms in question.

Conditions for Installation:

1 - TOLERATED MAXIMUM MOISTURE CONTENT OF THE SUB-FLOORING:

Cement Sub-floor / Sub-floor with hydraulic binders – 1.7% Anhydride Sub-floor: 0.2%

2 - HEATING OF THE SUB-FLOOR:

Turning on the heating system allows for the stabilization of the sub-floor, while discharging any tensions which may be present and establishing a degree of equilibrium and dryness corresponding to the environment conditions. Once the sub-floor is stabile, there is no risk of it transmitting moisture to the wood flooring once it has been installed.

3 - Presence of a barrier or vapour shield between the layer containing the heating system pipe work and the thermal insulation.

4 - Minimum sub-floor thickness of 6 cm, of which at least 3 cm must be located above the heating pipes.

5 - The minimum drying period required prior to turning on the sub-floor heating system:

CEMENT SUB-FLOOR: 21 days

ANHYDRIDE SUB-FLOOR: 7 days

CEMENT SUB-FLOOR WITH RAPID/VERY RAPID DRYING PERIODS: 3-4 days (depending on the instructions provided by the manufacturer)

6 - The heating has been turned on and the heating liquid temperature has been gradually increased in 10°C increments per day, until a maximum of 50°C is reached.

7 - The maximum temperature of 50°C was maintained for at least 10 consecutive days, while adequately airing out the various rooms.

8 - The cooling process was performed by gradually decreasing the temperature of the heating liquid 10°C per day until the temperature of +20°C is reached.

9 - The heating system was kept turned off for approximately 5 days prior to the installation of the hardwood floors. However, before laying the flooring, it is important to certify that the surface temperature of the sub-floor lays between 15-20°C with a relative ambient humidity of no more than 60%.

10 - The superficial temperature post-installation should not exceed 26°C. The use of thick carpets on your new wood flooring is not advisable as they may limit air circulation. The recommended ambient conditions to be maintained are a temperature between 18-21°C with a relative air moisture content varying between 50 – 60%.

SUB-FLOOR

It is essential that prior to the installation of your new parquet to ensure that the sub-floor has had ample time to stabilize. The former must be rid of excess moisture content, having attained the ideal hygrometric equilibrium required for the subsequent installation of hardwood flooring.

LAYING TYPES

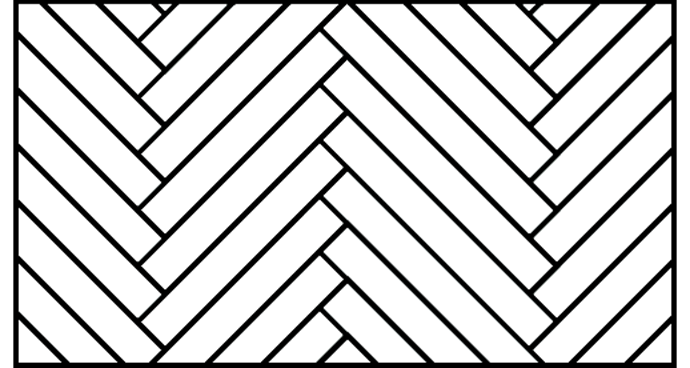

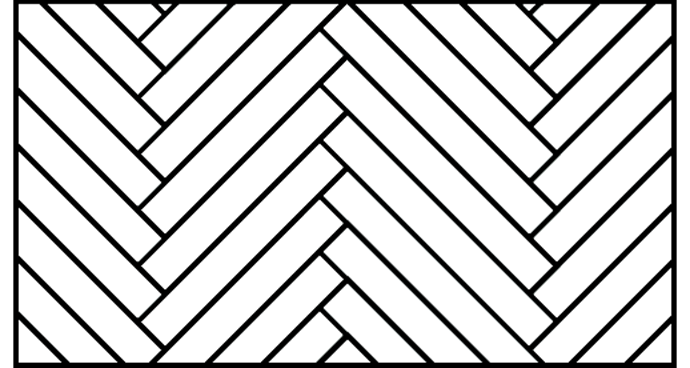

HERRINGBONE

The single elements are laid placing them 90°, in parallel rows, so that one element's head is interlocked to the other's lip. The Herringbone can be installed both straight or diagonal.

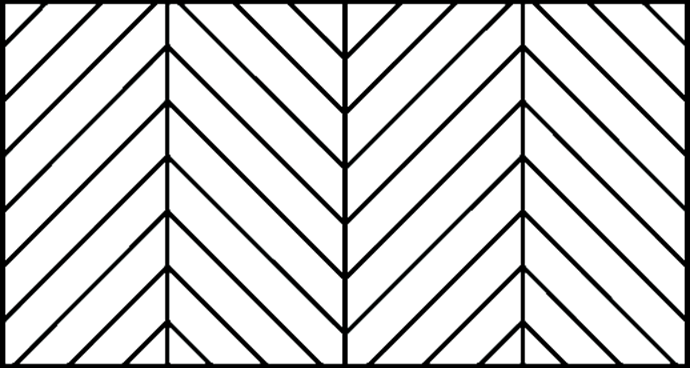

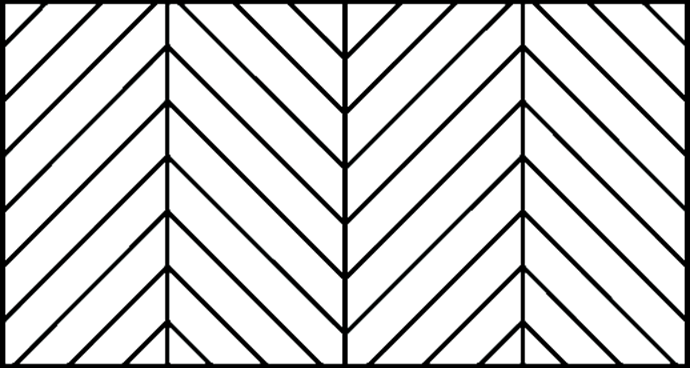

HUNGARIAN POINT (CHEVRON)

Similar to the herringbone, the only difference is that the short sides are cut 45° or 60°.

BLOCK LAYING

The elements are assembled in a square composition, repeated in the whole surface.

FRENCH STYLE

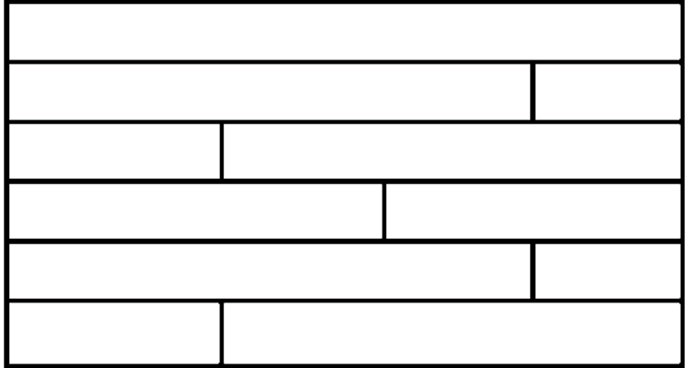

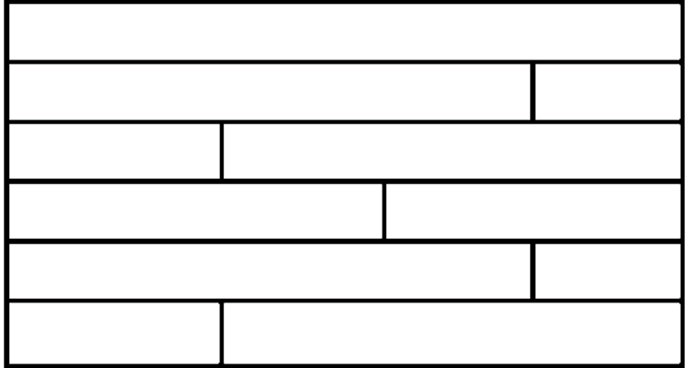

The single elements, have random lengths and also different widths laid longwise in parallel direction.

SHIPLAP

The single elements, have random lengths, are laid longwise, so that the ends are fitted irregularly.

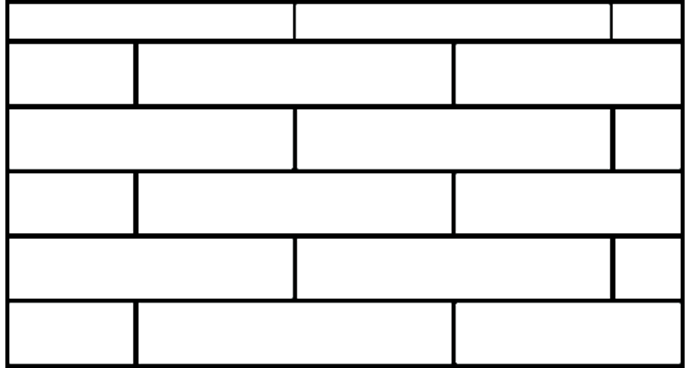

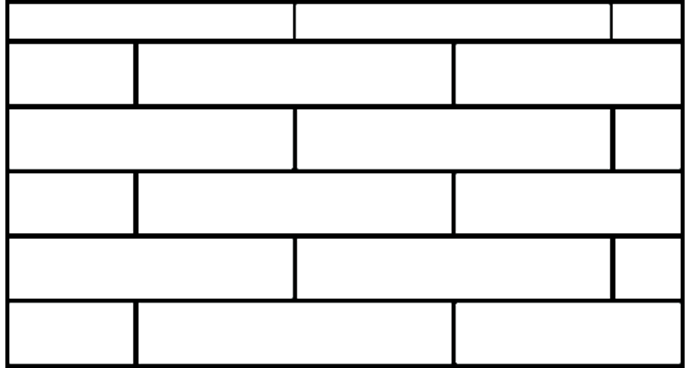

ENGLISH STYLE

The single elements have fixed width and length are laid longwise so that all joints are in the same and constant position as the previous row.

POSA A SPINA DI PESCE

POSA ALL'UNGHERESE

POSA ALLA FRANCESE

POSA A TOLDA DI NAVE O A CORRERE

POSA A CASSERO REGOLARE

POSA A SPINA DI PESCE

POSA ALL'UNGHERESE

POSA ALLA FRANCESE

POSA A TOLDA DI NAVE O A CORRERE

POSA A CASSERO REGOLARE

KEEP YOUR HARDWOOD FLOORS LOOKING THEIR BEST BY FOLLOWING THE INSTRUCTIONS OUTLINED BELOW:

In order to avoid shrinkage or other movement, such as cupping and excessive swelling in the wood flooring, it is recommended that on site the relative humidity be maintained between 45%-60% and temperatures between 20°C-22°C.

Under floor heating systems, without a correct humidification, can create cracks and fissures in any type of parquet and timber species.

Avoid loading small sections of the flooring with heavy and concentrated weights.

Do not cover the parquet with carpets and the like post-installation in order to avoid localised uneven tones attributed to the lack of light oxidation.

MAINTENANCE FOR OILED PRODUCTS

LINFOLEGNO: This product increases the floors resistance to water and prevents stains.

LINFOLEGNO should be used after laying. It can be used several times a year (with a single treatment) depending on the usage of the wood flooring: rooms once a year; living room, kitchens, bathroom, offices, stores, repeatedly throughout the year.

HOW TO USE IT: Shake well before using, do not dilute.

For new hardwood floors, once you have cleaned the floor using Mistrall soap diluted in the appropriate amount of water, pour LINFOLEGNO into a bucket. Using a cotton rag, apply the product on the desired surface. Please note that the rag should be well wringed-out. It is recommended that a thin veil of LINFOLEGNO be applied in the lengthwise direction of the plank, without leaving an excess of the product.

Let it dry.

After an hour a second treatment of product is applied in the same way. Wait at least 2 hours before walking on the parquet.

Note: To increase the floor's resistance to water, apply the LINFOLEGNO only once with the method described above.

MISTRALL: Neutral Detergent Soap

Ordinary Cleaning: Use a vacuum cleaner or a broom. To wash the floor, use MISTRALL soap at least once every two weeks. This same detergent can also be used on ceramic floor tiles, marble, etc.

Use: Half glass of MISTRALL soap in 8/10L of water and using a white cotton rag, well wringed.

MAINTENANCE FOR VARNISHED PRODUCTS

Ordinary Cleaning: Use a vacuum cleaner or a broom.

To wash the floor use a white cotton rag, water and MISTRALL soap only in case of necessity and follow instructions on the bottle.

IN EVERY WRAPPING OF MAINTENANCE PRODUCTS ARE ALL THE INSTRUCTIONS FOR USE.

Please keep in mind to never use alcohol, solvents and ammonia or any other products containing solvents or acids pure or diluted to clean your wood flooring.

Moreover, the crystallization of the oil or varnish coating on the surface and in the wood fibre only finishes 30 days post-installation. Therefore, it is necessary to take more caution soon after the installation of parquet (i.e. use shoes with rubber soles, do not to drag heavy furniture across the floor, etc.). We recommend that you protect your wood flooring by placing felt adhesives under your chairs and heavy furniture.

MAINTENANCE FOR THE SHABBY COLOURS COLLECTION

It is important to note, that when washing the floor, if abundant water is used (mop and bucket) the original bees wax spread on the planks will wash off. Please follow the instructions listed below: For Daily Cleaning: Use a vacuum cleaner.

When washing the floor, make sure to use a neutral soap (i.e Mistrall) and NO cleaning products that are very abrasive or include solvents in their formulas. In addition, do not use a mop soaked in water. Use a humid rag to clean, so as to conserve the bee's wax applied during the finishing of the planks.

Should you find the necessity to re-apply the wax, use a paintbrush to spread the wax over the floor. Wait a couple of hours for it to dry, and then using the special steel wool pad included with the bee's wax upon delivery, slowly work the floor until all the planks are uniform in colour and texture.

MAINTENANCE PRODUCTS

LINFOLEGNO (for oiled wood flooring)

To increase the water resistance of your hardwood floors, this product is ideal. It is a micro emulsion of valuable waxes, resins and modified oils for the protection of parquet floors. This product should be applied only once the floor has been treated with oil beforehand. Linfolegno ensures a rapid and easy application, maintaining the surface's natural appearance, nourishing it, and above all protecting it's natural beauty while giving it a full-bodied and pearly glow.

Advantages & Characteristics:

- Provides strong water resistance

- It doesn't whiten even if water remain on the floor one whole day

- Effective protection from everyday use

- Product doesn't contain solvents

- It allows transpiration (over 80%)

- Bio degradable up to 90%

INSTRUCTIONS FOR USE:

Shake well before using, do not dilute. Pour a small quantity of Linfolegno on the floor and spread with a cotton rag, creating a thin film. After an hour a second treatment of product is applied, in the same way.

YIELD: 14-18m2/L per application

MISTRALL (Neutral Soap)

Mistrall is the fruit of careful research, created using a highly concentrated special formula suitable for the cleansing and maintenance of a variety of surfaces. Thanks to its special formula, Mistrall not only sterilizes and brings shine to any surface, but also aids in the prevention of molds, bacteria, and germs. In addition, Mistrall has been formulated to clean a diversity of surfaces including terracotta tiles, stone floors, marble, ceramic, etc.

Advantages & Characteristics:

- Detergent with low foaming

- It doesn't require rinsing

- Cheap (as a small dosage is required)

INSTRUCTIONS FOR USE:

For ordinary cleaning dilute 2-5% (half a glass) of Mistrall in a bucket with approximately 10L of water, and clean with a wrung out cotton rag. Rinsing is not required.

YIELD:

With 10L of Mistrall (diluted at 2-5%) can be cleaned 100 m2 of flooring.

BONA PARQUET POLISH (for Varnished Wood Flooring)

Bona Parquet Polish is a ready-to -use waterborne, maintenance product reinforced with polyurethane and specifically designed for use on finished wooden surfaces.

INSTRUCTIONS FOR USE:

Ensure surface is clean and dry. Do not use on any floor that has been waxed. If the surface has been treated before with a different type of polish, unknown or factory pre-finished treatment, make a test on small area to ensure compatibility. Shake the container before use.

Apply using the microfiber applicator pad for a smooth surface. String mops, cotton mops, sponge mops or similar are not recommended for application. Apply a consistent layer on the flooring surface. Avoid to work on areas dried as this may create streaks. Wait at least 1 hour before walking on the parquet. If necessary, repeat the treatment twice.

YIELD:

50m2/L per application